How a New ARENA Grid System Transformed the Mississippi Coast Coliseum

A behind-the-scenes look at how Conder Truss, XSF and a winning team delivered a structural overhaul that brought world-class shows back to Biloxi. Talk to a Truss ExpertVenue:

Mississippi Coast Coliseum

Year Built:

1976 (Upgraded in 2024)

Annual Visitors:

500,000+

Setup Time Reduced:

50%+

Event Type Supported:

Concerts, Ice Shows, Touring Productions

Truss Fabrication:

100% USA-Made by XSF

Arena GRID Truss System Install Team: Conder Truss

For decades, the Mississippi Coast Coliseum has been a place where big things happen. Concerts, fairs, dance competitions, you name it, and this venue has hosted it.

Built in 1976, it’s been a major part of the local economy, drawing more than half a million visitors a year. These guests bring life to the area, spending money in restaurants, casinos, shops, and hotels.

But behind the scenes, the building had a problem. One that cost it time, money, and opportunities.

The Challenge: A Square Grid in a Round Dome

“Trying to fit a square rigging grid into a round dome was no easy task—but the collaboration made it possible.”

– Michael from Simpkins & Castelli

Most people in the audience never think about rigging.

It’s the system used to hang lights, sound, and staging equipment above the arena floor.

But for the crews that travel from city to city putting on shows, rigging is everything.

And for too long, the Coliseum was known as one of the hardest places to rig in the region.

Touring professionals and artist managers avoided the venue because the setup was too slow, too expensive, and often needed an extra day just to hang equipment from the roof.

That meant fewer shows, higher costs, and frustrated crews.

Something had to change.

"The Coast Coliseum was known as one of the hardest places to rig in the region."

A Plan Comes Together | Arena Grid Truss System

Thanks to a grant from the BP Restore Act and strong leadership at the Coliseum, the team had the funds to make a long-overdue upgrade: a brand-new arena grid.

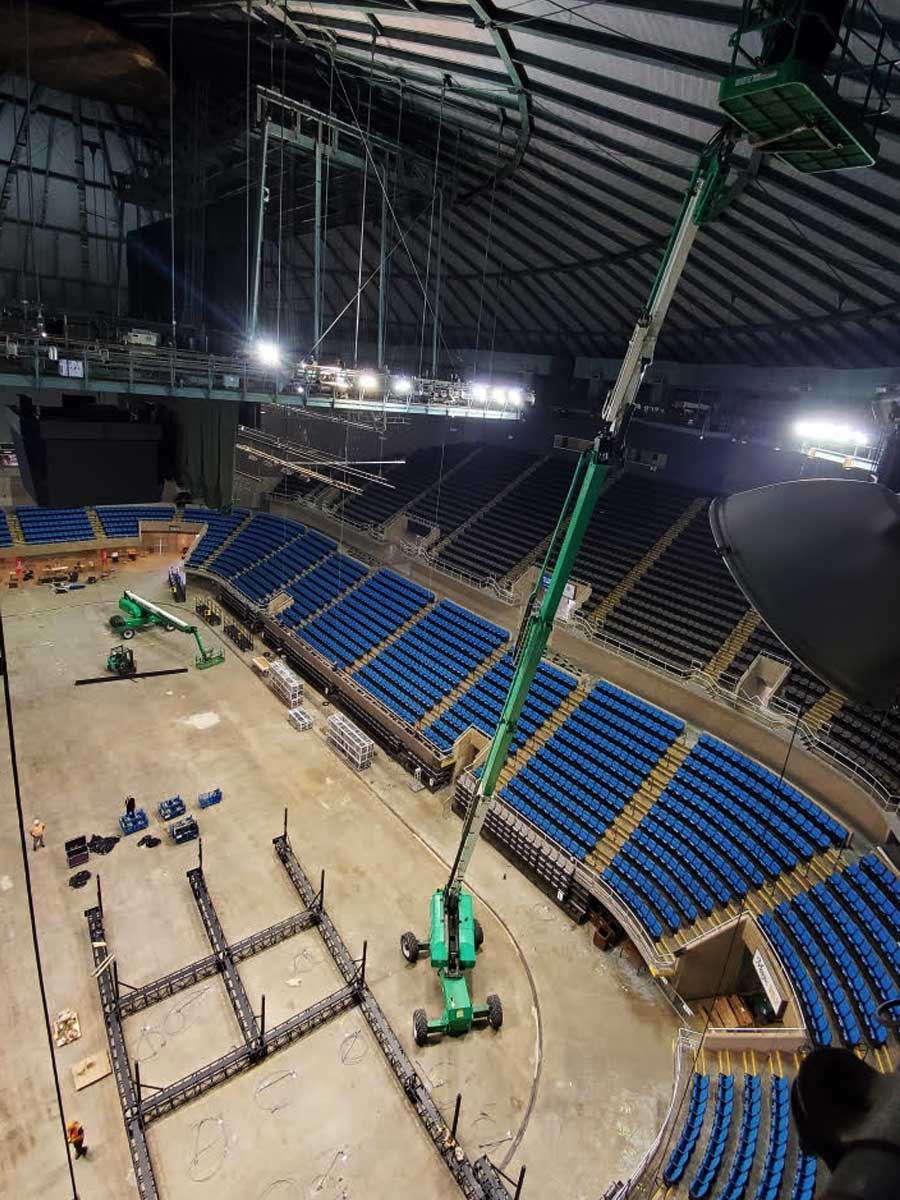

But this wasn’t a small fix. It was a massive redesign of the building’s entire overhead rigging system. To pull it off, the Coliseum needed experts in engineering, fabrication, and installation.

That’s where Conder Truss and XSF Truss came in. Conder Truss led the installation, while XSF’s in-house test fit and custom fabrication ensured everything arrived ready to fly—with no surprises.

Grid Sizes:

Main Grid: 107′ X 58′

Secondary Grid: 70’ x 31’

Primary Products Used:

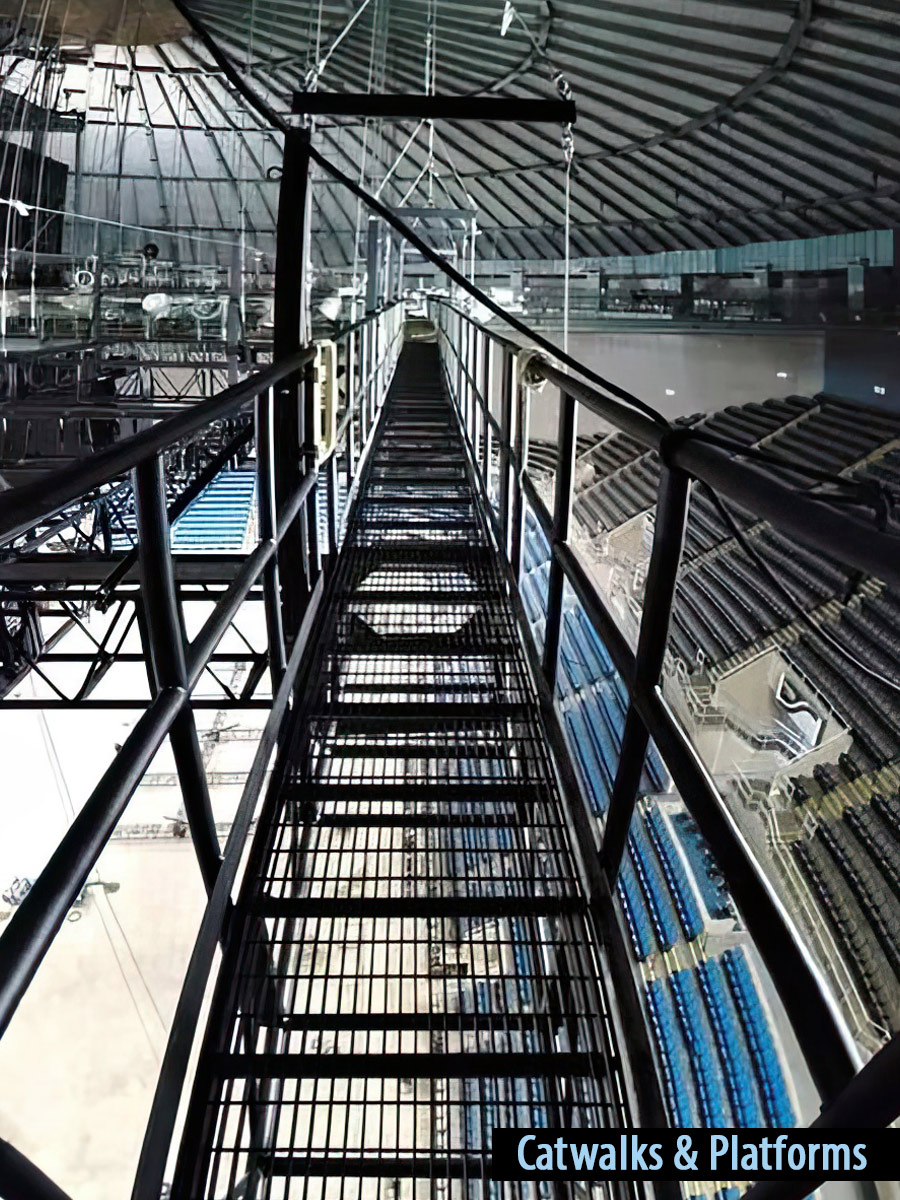

20.5” x 32” Catwalk Truss

24” x 20.5” Arena Grid Truss with walk surface

Weight Capacity:

Main Grid: 120,000 lbs.

Secondary Grid: 101,000 lbs.

Additional Information:

All truss, catwalks and HLL components are powder coated black

The Power of Partnership

Conder Truss played a crucial role from day one.

As the East Coast distributor for XSF Truss, they knew exactly how to bring the right team, gear, and know-how together.

Working closely with XSF, Conder Truss helped pre-plan the system.

Making sure every part would perform as needed, from the first lift to the final bolt.

Their understanding of large-scale installations meant nothing was left to chance.

And because XSF Truss fabricates everything in-house in Sulphur Springs, Texas, they were able to test-fit the entire grid before it ever left the shop. That’s a game-changer. When it arrived on-site, everything fit exactly as designed.

From the grid to the platforms and catwalks, the entire system came together seamlessly; its a testament to the planning, precision engineering, and teamwork behind the project.

“It’s exciting seeing something like that being executed, knowing what it took to get to this point,” said one team member during installation, which was a feeling echoed across the crew as the grid took shape overhead.

Team Work that Transformed the Mississippi Landmark

From engineering to welding, every hand on this project mattered.

This wasn’t just an installation, it was a shared vision. Engineers, riggers, fabricators, and local staff came together to modernize a landmark. The result? A rigging system everyone takes pride in, built by people who care deeply about the shows and stories this venue will continue to host.

Building the New Backbone

The Coliseum’s old rigging setup wasn’t just outdated.

It was limiting.

The engineers had to work with a geodesic dome roof, which made fitting a square rigging grid extra tricky.

No original structural drawings existed, so the engineering team had to scan, model, and carefully plan every move.

Working together, XSF and Conder helped design an aluminum truss grid that was both lightweight and incredibly strong.

Compared to steel, aluminum was the better choice.

It reduced the load on the roof and was easier to install.

The new grid system is laid out in a 15-foot by 15-foot pattern, offering far more rigging points than before.

It allows big shows, to load in and out quickly and safely.

In fact, what used to take two full days can now be done in one efficient morning!

Results That Make a Difference and the differences are just more than visual.

The New Arena Grid Installation means:

-

-

- Faster setup times

- Fewer riggers needed

- Lower labor costs

- Less equipment required

- More shows, bigger shows and more revenue

-

When it was time to build, Conder Truss was the lead installation contact on-site. They brought the crew, organized the schedule, and made sure every piece of the puzzle came together. With lifts reaching up to the ceiling and hoist packages installed, the team flew each section of the grid into place, working in stages.

Despite the complex shape of the dome and the custom engineering involved, the install went smoothly, thanks to Conder’s leadership and XSF’s precise fabrication.

“We’re not an old-school 1977 Coliseum anymore,” said one staff member. “We’re upgraded, and this rigging system puts us in a whole new league.”

What used to be a frustrating venue is now a rigging-friendly powerhouse. Load-ins that once needed 10 hours and a day of pre-rigging now happen in 4–5 hours, same day. Crews aren’t dealing with dangerous boom lifts or awkward bridles.

It’s safer, smoother, and more professional all around. And word is getting out.

This grid is more than a piece of infrastructure, it’s a reason for the country’s biggest shows to come back to Biloxi.

And the team that made it happen, Conder Truss, XSF Truss and Simpkins & Castelli are proving what happens when you mix smart planning, precise fabrication, and and experienced installation.

The Mississippi Coast Coliseum now has the load capacity, flexibility, and performance to compete with the best venues in the US.

“Trying to fit a square rigging grid into a round dome was no easy task—but the collaboration made it possible.”

“We’re not just a 1977 venue anymore this upgrade brings us into the future of live entertainment.”

30 Minute Trussumentary Video & 1 Minute Time-Lapse Build

Arena Grid Installation at Mississippi Coast Coliseum

A massive upgrade to a historic venue. Get a behind the scene look of this Arena System Grid Installation at the Mississippi Coast Coliseum.

Time-Lapse Grid Installation | Mississippi Coast Coliseum

Watch the entire Arena Grids system built in this 1 minute Time-Lapse Video.

TRUSS YOU CAN COUNT ON

Need Truss? Call Conder

Whether you’re upgrading an arena, building a new structure, or just need expert advice, Conder Truss is the team to call.

As the official East Coast distributor for XSF Truss, we bring tested, proven systems to jobs of every size and we install what they sell.

With 100% USA-made truss and full test-fit procedures at XSF’s Texas facility, you’ll never have to worry about things not lining up on-site.

- Premier East Coast Distributor for XSF Truss

- 25+ Years of Industry Experience

- High-Quality Equipment & Rigging Parts

- Custom Solutions Tailored to Your Project

- Consistent, Open Communication with Every Client